None

The digital landscape is evolving at a breathtaking pace. From the seamless streaming of 8K content and the immersive worlds of the metaverse to the mission-critical automation of smart cities and Industry 4.0, our hunger for data is insatiable. This surge is propelled by next-generation technologies like 5G, Fiber-to-the-Home (FTTH), and the Internet of Things (IoT), all demanding unprecedented bandwidth, lower latency, and hyper-connectivity.

While much attention is given to the sophisticated hardware in data centers and the sleek devices in our hands, the true unsung hero of this digital revolution is often buried underground, strung along poles, or snaking through conduits: the outdoor optical cable.

The Backbone of Modern Connectivity: More Than Just a Wire

At its core, an optical fiber cable is a strand of pure glass designed to transmit data as pulses of light. This fundamental technology offers immense advantages over traditional copper cabling, including vastly higher bandwidth, longer distances without signal loss, immunity to electromagnetic interference, and enhanced security.

However, not all fiber cables are created equal. The crucial differentiator lies in the environment they are designed for. Indoor fiber optic cables are protected from the elements within buildings and data centers. Outdoor fiber optic cables , on the other hand, are engineered to survive and thrive in the harsh, unpredictable conditions of the outside world. This distinction is critical for the integrity of the entire network.

The Unique Challenges of the Outdoor Environment

Deploying cable outdoors subjects it to a relentless battery of stressors that indoor cables never face. A cable designed for outdoor use must be built to withstand:

Temperature Extremes: From scorching summer heat that can soften materials to freezing winter cold that can make plastics brittle and contractive.

Moisture and Water Ingress: This is the primary enemy. Water penetration can lead to signal attenuation (degradation) and, in freezing conditions, catastrophic ice damage within the fiber buffer tubes.

UV Radiation: Prolonged exposure to sunlight can degrade and crack standard plastic jackets, weakening the cable’s protection.

Physical Stress: Wind, ice loading on aerial spans, rodent attacks, abrasion against rocks in direct-buried trenches, and construction activity.

Chemical Exposure: Resistance to oils, solvents, and other chemicals sometimes present in soil or industrial environments.

Failure to use a cable specifically designed for these conditions can lead to frequent network failures, exorbitant maintenance costs, and costly total replacements long before their expected lifespan.

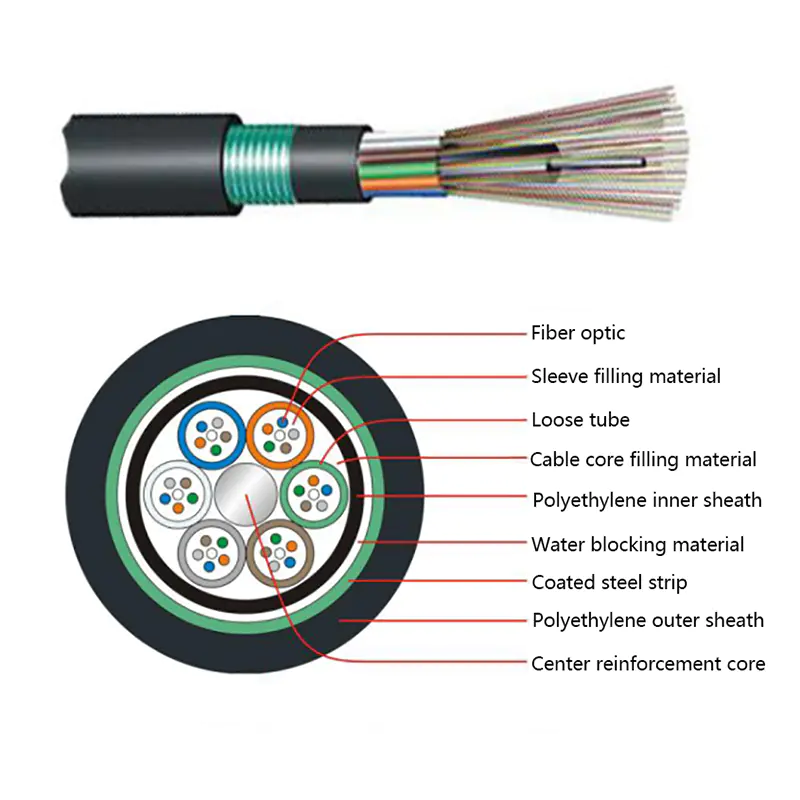

Anatomy of a Ruggedized Outdoor Cable: Built for the Battlefield

So, what makes an outdoor-rated fiber cable so durable? It’s all about the protective layers and materials engineered into its design. Understanding this anatomy is key to specifying the right cable for the right application.

The Fiber Core: The heart of the cable, typically single-mode fiber (SMF) for long-haul and FTTx applications due to its high bandwidth and long-distance capabilities.

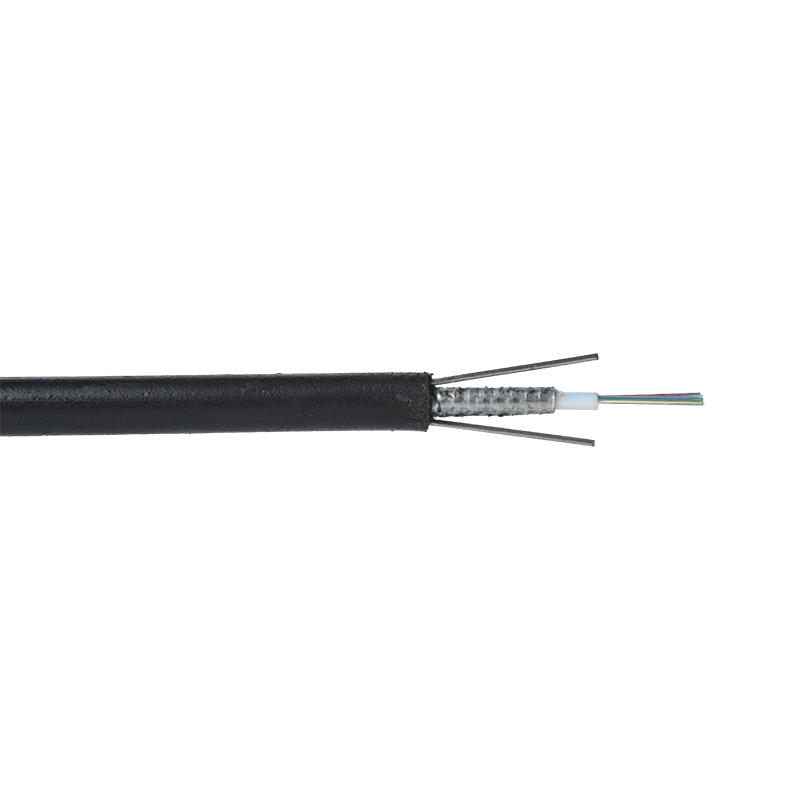

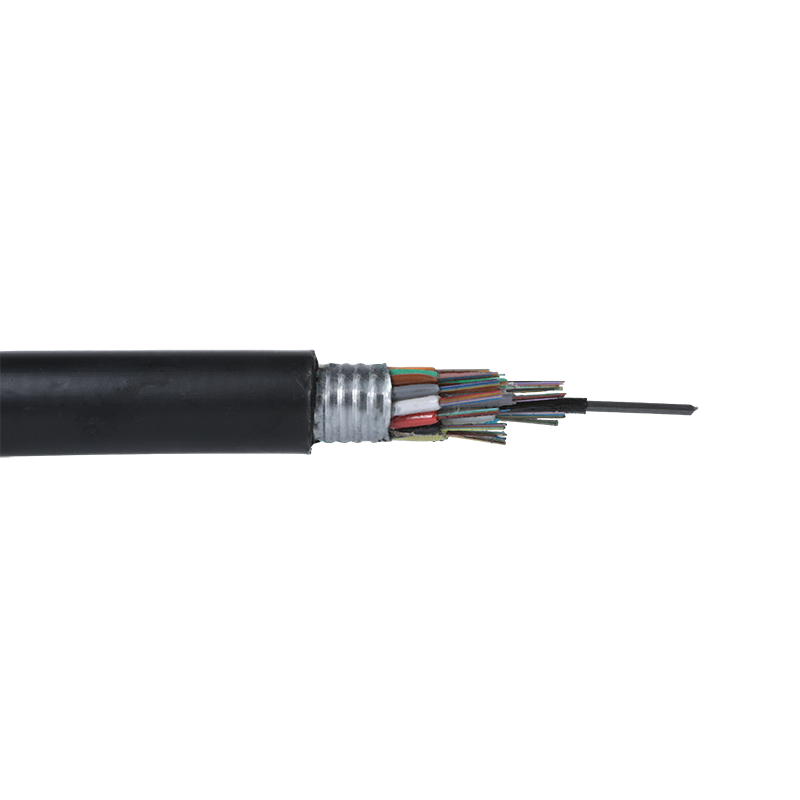

Buffer Tube: The individual optical fibers are housed within colored, flexible plastic tubes. These tubes are often filled with a water-blocking gel or, in more modern designs, employ dry water-blocking technology using tapes and yarns impregnated with super-absorbent polymers. This prevents water from traveling along the length of the cable if the sheath is breached.

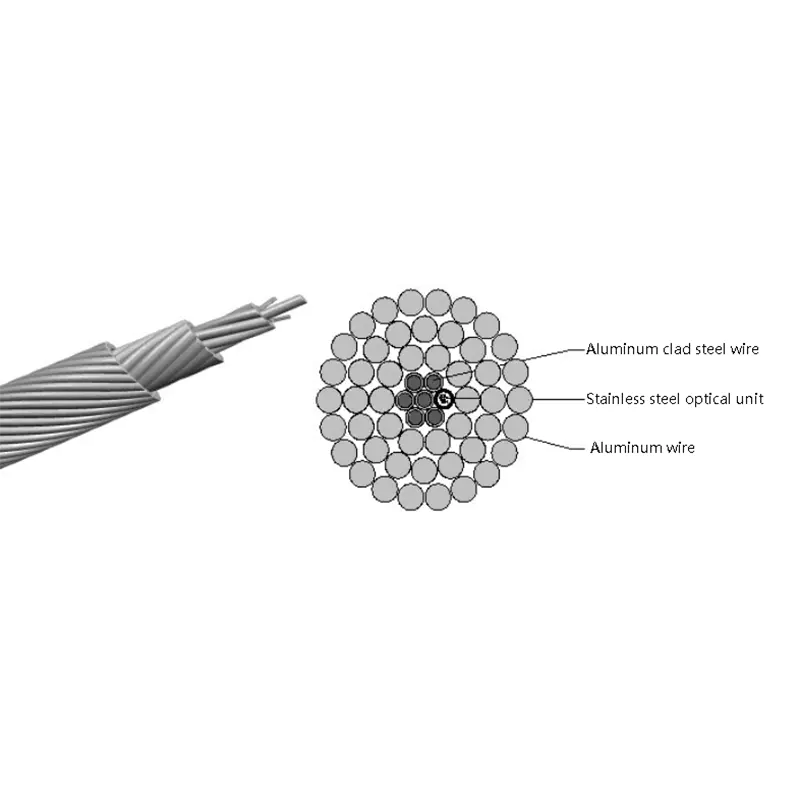

Strength Members: A critical component for aerial fiber deployment and pulling cables through conduits. Central strength members, often made of fiberglass or steel, provide tensile strength to withstand installation pulls and constant gravitational loads. Aramid yarns (like Kevlar®) are also woven around the buffer tubes for additional reinforcement and resistance to stretching.

The Outer Jacket: This is the first line of defense. For outdoor cables, the jacket is made of tough, high-density polyethylene (HDPE). HDPE is chosen for its excellent moisture resistance, wide temperature tolerance, and high resistance to abrasion, UV radiation, and environmental stress cracking. For direct burial fiber optic cable , the jacket may be corrugated steel tape armored (CST) to resist crushing and rodent bites.

This robust construction ensures a long service life, typically exceeding 25 years, even in demanding environments, making it a cornerstone of durable network infrastructure .

Key Applications Driving Demand for Outdoor Fiber

The strategic deployment of outdoor fiber is enabling every major advancement in connectivity.

5G Network Backhaul and Fronthaul: The promise of 5G—multi-gigabit speeds and ultra-low latency—is not delivered solely by wireless towers. Each macro cell and small cell must be connected to the core network with incredibly high-capacity fiber links. This fiber optic backhaul solution is the non-negotiable backbone of 5G. Dense, urban 5G deployments require a massive web of outdoor fiber to connect thousands of nodes.

Fiber-to-the-Home/Business/Curb (FTTx): The global push to replace aging copper lines with future-proof fiber is entirely dependent on outdoor cable plants. FTTH drop cable and distribution cables are deployed aerially on poles or buried underground to finally bring limitless bandwidth to end users. This is the most visible and impactful use case for most consumers.

Smart City Infrastructure: Modern cities are deploying vast networks of sensors, cameras, and IoT devices to manage traffic, public safety, energy grids, and environmental monitoring. These devices require reliable, high-speed, and secure connections that only a dedicated outdoor fiber network can provide, forming the nervous system of the smart city.

Long-Haul and Metropolitan Area Networks (MANs): Connecting cities, data centers, and countries requires cables that can traverse hundreds of kilometers through diverse terrains—mountains, deserts, and riverbeds. These long-distance fiber links are the superhighways of the internet, built with the most robust and high-capacity outdoor cables available.

Deployment Considerations: Aerial, Underground, and Direct Buried

Choosing the right installation method is as important as selecting the right cable. Each method has its own requirements and corresponding cable designs.

Aerial Installation: Involves lashing or wrapping cables to existing telephone poles or deploying self-supporting cables like ADSS (All-Dielectric Self-Supporting) cable, which has built-in strength members to hold its own weight without a metal messenger wire. This method is often faster and more economical than trenching but exposes the cable more directly to the elements.

Underground in Conduit: Placing cables inside a protective conduit (plastic or metal pipe) buried underground offers excellent physical protection from weather, excavation, and rodents. While the initial cost is higher due to the conduit installation, it provides a protected pathway for future cable upgrades and is generally considered the most secure and long-lasting method.

Direct Buried: As the name implies, direct burial fiber optic cable is designed to be placed directly into the ground without a conduit. These cables are the most heavily armored, typically with a corrugated steel tape armor layer and a thick PE jacket to resist crushing, moisture, and rodent penetration. This is a common method for long-haul routes across rural areas.

Future-Proofing Our World: The Long-Term Value Proposition

Investing in a high-quality outdoor fiber optic infrastructure is not an expense; it is a long-term strategic investment. Here’s why:

Vast Latent Capacity: A single strand of modern single-mode fiber has virtually unlimited theoretical capacity. The technology upgrades happen at the endpoints (lasers and detectors), not the cable itself. Deploying a fiber cable today means the physical medium will not need to be replaced for decades; we can simply light more of its inherent capacity with new transceiver technology (e.g., moving from 10G to 100G, 400G, and beyond on the same fiber).

Low Total Cost of Ownership (TCO): While the initial material cost of fiber may be higher than copper, its longevity, minimal signal loss (reducing the need for repeaters), and resistance to failure lead to significantly lower maintenance and operational costs over its 25 year lifespan.

Scalability and Flexibility: A robust outdoor fiber network can easily be tapped into to support new developments, 5G small cells, or business parks without requiring entirely new infrastructure builds. This scalability is essential for accommodating unpredictable future growth.

Choosing the Right Outdoor Cable: A Quick Guide

Specifying the correct cable is paramount. Key considerations include:

Environment: Will it be aerial, in conduit, or direct buried? Is it a high-rodent area?

Fiber Count: Plan for future growth. Installing a cable with higher fiber count than currently needed is a cost-effective way to future-proof the infrastructure.

Jacket Type: Standard PE for general use, or LSZH (Low Smoke Zero Halogen) for installations in ventilation shafts or enclosed areas where fire safety is a concern (e.g., tunnels).

Armoring: Specify armored cables for direct-burial applications or in areas with a high risk of physical damage.

Water Blocking: Gel-filled or dry-breakwater technology? Dry designs are often preferred for easier, cleaner splicing, reducing installation time.

Conclusion: The Unseen Foundation of a Connected Future

As we stand on the brink of a new era defined by artificial intelligence, ubiquitous automation, and immersive digital experiences, the reliability of our underlying network has never been more critical. The exciting applications that capture headlines are entirely dependent on the silent, resilient work of outdoor optical cables.

These cables are far more than simple conduits for light; they are the durable, high-capacity arteries of our global digital economy. By prioritizing the deployment of high-quality, purpose-built outdoor optical cables , municipalities, service providers, and enterprises aren’t just solving today’s connectivity challenges—they are laying a proven, future-proof foundation for the innovations of tomorrow. Investing in this physical layer is the most crucial step in building a next-generation network infrastructure that is both powerful and enduring.

English

English русский

русский Español

Español عربى

عربى 中文简体

中文简体